End-to-End LED PCB Design Solutions Tailored to Your Industry Needs

Whether you need prototypes or volume production, Casyoo delivers flexible, high-quality LED PCB design services with comprehensive testing and international compliance, enabling you to accelerate your path to market.

Experienced Team

Decades of cross-industry PCB design experience with deep technical expertise.

One-Stop Solution

From schematic to layout to DFM, we offer complete end-to-end PCB design services.

Fast & Reliable Turnaround

Optimized workflow ensures quick prototyping and smooth transition to volume production.

Precision & Optimization

Prioritize high-speed signal integrity, thermal management, and EMI/EMC mitigation for robust performance.

Full-Spectrum PCB Design & Layout Workflow

Requirements Analysis

We listen carefully to your needs and define precise design targets based on technical and application-specific requirements.

Schematic Design

Our engineers create and refine schematic diagrams to ensure functional integrity and design clarity from the ground up.

Component Selection

We source optimal components based on performance, availability, and cost, while maintaining a well-managed part library.

Stack-Up & Impedance

Custom layer stack-ups are engineered to ensure signal integrity, EMI performance, and mechanical stability.

Placement & Thermal

Critical components are positioned for optimal electrical and thermal performance, enabling efficient cooling and compact layouts.

Signal & Power Routing

We apply advanced techniques like differential pair routing and power/ground plane management to preserve signal and power integrity.

Verification & Optimization

All designs go through thorough electrical rule checks, manufacturability reviews, and testability validations before sign-off.

File Package Delivery

We generate clean, ready-to-use Gerber and production files to support smooth transition into fabrication and assembly.

Design Optimization Focus Areas

Signal & Power Integrity (SI/PI)

We ensure stable, accurate data transmission and minimize noise with expert signal and power delivery network design.

EMI/EMC Compatibility

Our layouts are engineered to reduce radiated and conducted emissions, helping your product meet global compliance standards.

Thermal Management

Strategic thermal management techniques for LED PCB are embedded into our layouts to enhance product reliability and extend lifespan.

Design for Manufacturability & Testability (DFM & DFT)

By considering assembly and test constraints early in the design, we reduce production risks and enable faster time to market.

Cost-Optimized Design

We balance performance with smart material selection, layout efficiency, and simplified routing to lower your overall production cost.

Our Technical Capabilities

Feature

Specification

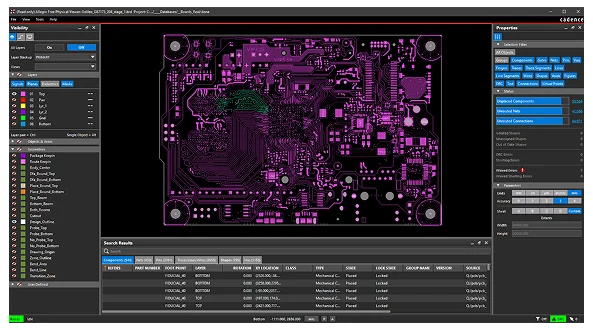

PCB Design Tools & Certification

At Casyoo, we leverage top-tier PCB design software to ensure precision, performance, and seamless compatibility with global manufacturing standards.

- Altium Designer

- Cadence (ORCAD & ALLEGRO)

- Autodesk (EAGLE)

- KiCad

Compliant | Certified | Trusted

Every PCB design at Casyoo strictly adheres to international industry standards, including: IPC-2221 /IPC-2222, IPC-A-610 Class 2 & Class 3. In addition, we maintain strong partnerships with global certification bodies, and can assist in obtaining product certifications including: UL, ETL, CE, FCC, and RoHS.

Why Choose Casyoo?

End-to-End Integration from Design to Production

We provide full in-house capabilities — from initial schematic to mass production — ensuring seamless transitions, faster delivery, and lower communication costs.

Application-Focused Engineering Expertise

Our team specializes in complex PCB designs for power systems, RF modules, industrial controls, and LED lighting — with a track record of delivering stable, production-ready solutions for high-reliability applications.

Design for Manufacturability & Cost Optimization

We design with manufacturing in mind. All layouts are optimized for mass production, component sourcing, and testability — reducing rework, delays, and overall cost.

Rapid Prototyping & Scalable Delivery

Thanks to our flexible process and efficient production lines, we support quick prototyping in days and smoothly scale to large-volume orders, helping you accelerate time-to-market.

Scalable Partnership with Global Brands

We’re a long-term partner to clients across North America, Europe, and Asia — trusted by industry leaders for our engineering reliability, responsive communication, and scalable production support.

2006

Founded in

470

Employees

100+

Engineers

29,500㎡

Floor space

10,00,000 pcs

PCBA per month

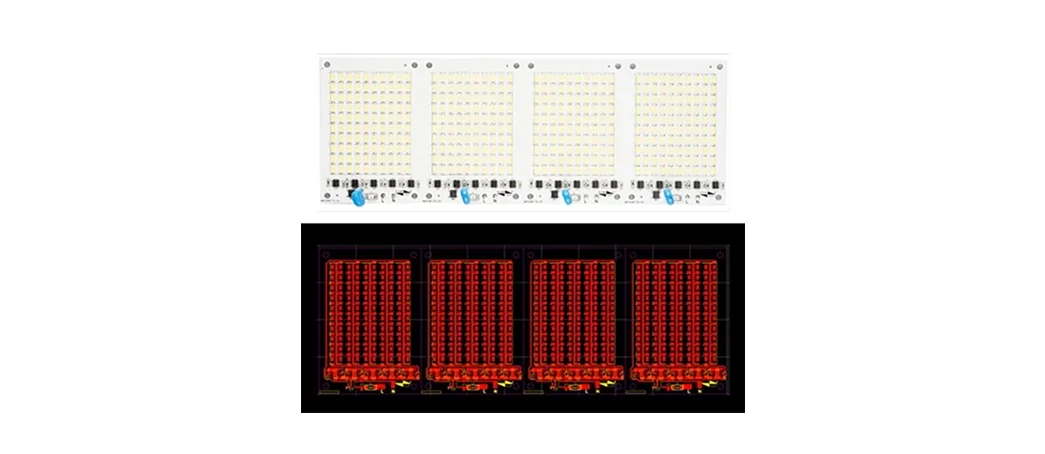

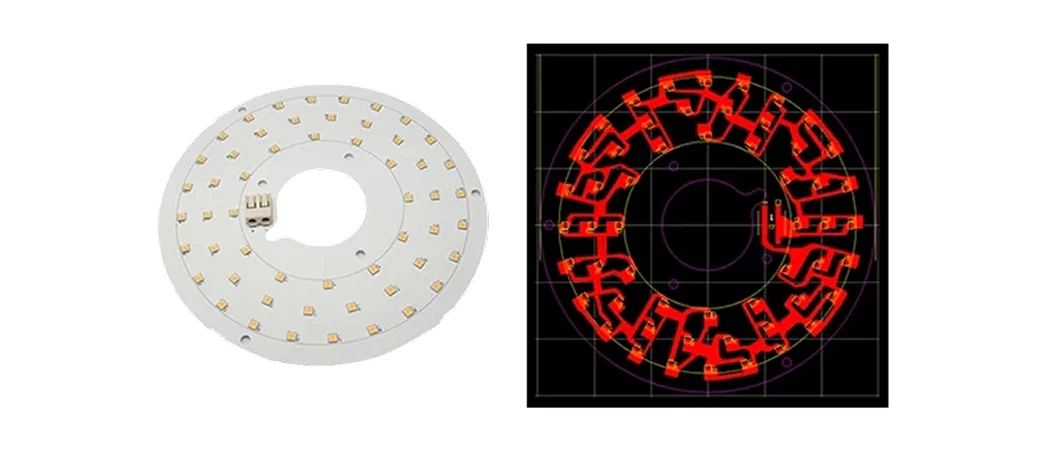

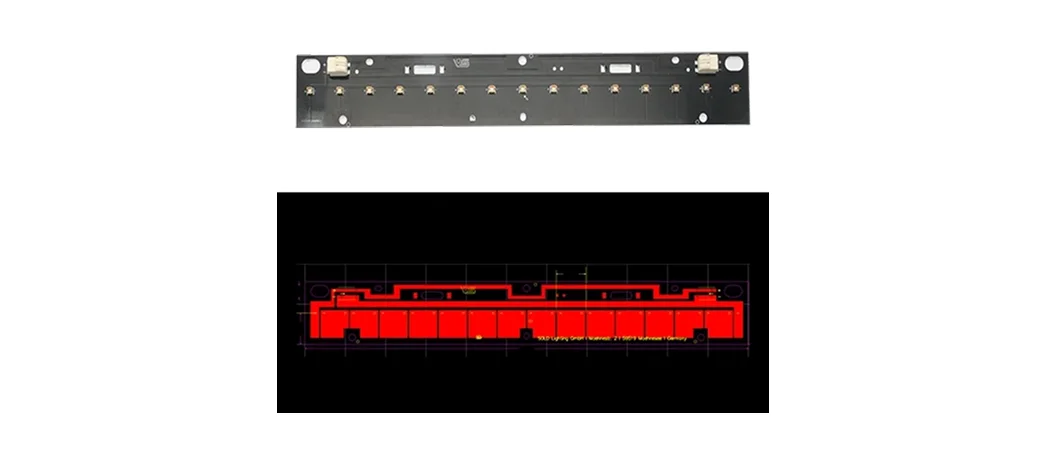

Successful Project Development Case

Casyoo provides a wide range of LED PCB designs and layout schemes based on the realistic needs of our clients. AC220V LED PCB, UV395NM LED PCB, Nichia LED PCB and 5050 RGB LED PCB are our products recognized by most of our customers.

AC220V LED PCB

UV395NM LED PCB

Nichia LED PCB

5050 RGB LED PCB

Frequently Asked Questions

How long does the PCB design process take?

Our standard production time ranges from 3-5 days for standard PCBs. Expedited services are available with turnaround times as quick as 24 hours.

Do you offer prototyping and component selection services?

We accept Gerber files (RS-274X), ODB++, Excellon, DXF, and other standard industry formats. For PCBA, we require BOM (Bill of Materials) and component placement files.

What information do you need to start a PCB design project?

Typically, we’ll need your project requirements, schematics (if available), any specific component preferences, mechanical constraints, and performance goals. Even a detailed concept is a great starting point.

Do you have a minimum order quantity (MOQ) for design projects?

No, we don’t have a minimum order quantity for design projects. We’re equipped to handle everything from single prototypes to large-scale production designs.

How do you ensure the confidentiality of my design and intellectual property?

We take IP protection very seriously. We’re happy to sign Non-Disclosure Agreements (NDAs) before any detailed discussions begin, and all project data is handled with strict confidentiality protocols.