Lumen maintenance is a ratio comparing the luminous flux of an LED light after a certain number of working hours to its initial luminous flux. Almost every LED manufacturer claims a lifespan of over 10,000 hours for their LED lights, rendering this indicator somewhat meaningless. When seeking to understand the true lifespan of an LED light, another crucial parameter comes into play—lumen maintenance.

What does lumen maintenance indicate?

According to the Illuminating Engineering Society (IES) standard, when an LED light has operated for 25% of its rated lifespan, typically around 6000 hours, the luminous flux should still be more than 70% of the original value. This standard is known as L70. The significance lies in the fact that LED lights don’t abruptly fail; instead, they experience a gradual decay in brightness. Once the luminous flux falls below 70% of the initial value, the light will not be bright enough. A low lux level will influence the performance of LED lights, especially in demanding applications such as street lighting.

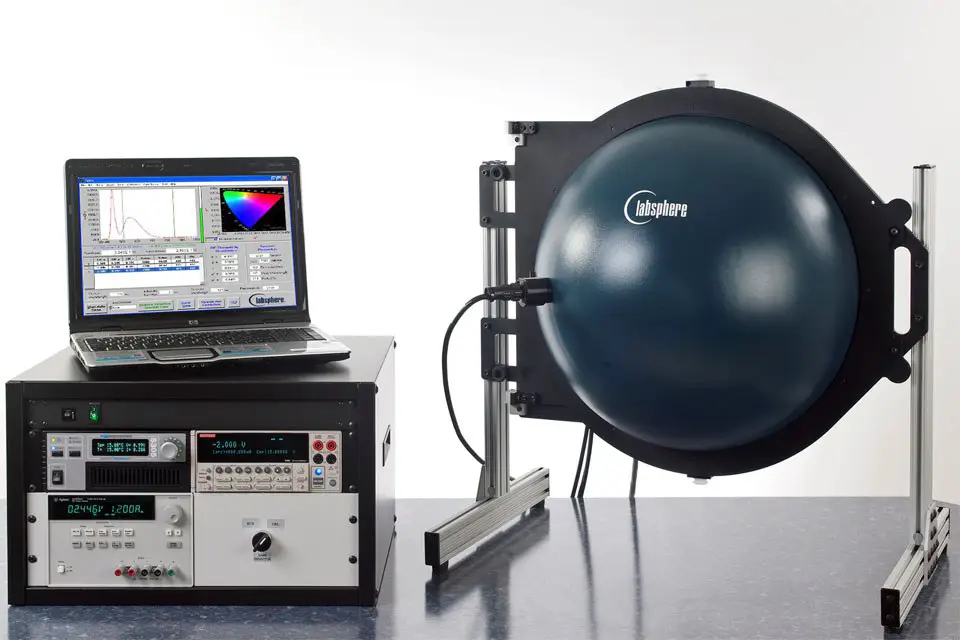

Lumen maintenance tests: LM-80 and TM-21

LM-80, introduced by IESNA, serves as a method for measuring the lumen maintenance of LED modules and fixtures. This extended test, usually spanning more than 6000 hours, aims to verify changes in LED light source performance influenced by factors like ambient temperature, airflow, and direction. Lumen output is tested under three different currents at 55°C, 85°C, and a specified temperature. After 6000 hours, the lumen output is compared with the original to determine if the light source meets the L70 standard.

Building on the LM-80 test, the TM-21 test predicts the actual lifespan of LED lights. It performs a curve fit on LM-80 data, calculating the precise moment when lumen output drops below 70%. This offers a clearer understanding of how long LED lights last.

However, the LM-80 has limitations. The test will not consider those LED lights that failed during testing, leading to potentially inaccurate results. To enhance reliability, LM-80 tests should follow LED reliability qualification testing, ensuring all lights are functioning normally. Even though failed LED lights don’t contribute to lumen maintenance results, ES (Energy Star) requires that these failure be noted in the report. Some reliable manufacturers also increase sample quantities to avoid the influence of LED light failure. So it is necessary to look for notes and sample numbers in the LM-80 report.

Conclusions

Lumen maintenance is a precise parameter that indicates the lifespan of LED lights. LED lights commonly expire due to light decay, making the LM-80 and TM-21 tests important for evaluating performance over 6000 hours. These tests remain among the most effective methods for estimating LED light lifespan despite potential influences from LED failures.

Even though the light decay of LED lights is inevitable, there are lights that can keep high lumen maintenance for a relatively long time. What you need to do is to contact reliable manufacturers like Casyoo to make sure the lights are up-to-standard.