When purchasing LED in bulk, the prosperity of your business rests on a manufacturing partner that provides unnegotiated quality and performance. At Casyoo we do not just produce LED lights, we are engineers of illumination who meticulously build light form the foundation. This comprehensive guide to LED light manufacturing process looks at how we make our LED lights shows the extreme measures and leading edge technologies that go into making each product we ship to you the very best in reliability, efficiency and consistency. Take a closer look and find out the Casyoo difference.

LED Chip Manufacturing Process

1. Crystal Growth and Material Choice

Most LEDs use Gallium Nitride (GaN) and Indium Gallium Nitride (InGaN) to produce white, green and blue light, and Gallium Arsenide (GaAs) to produce red and infrared.

To achieve the performance and reliability of LED chip, we adopt high quality substrates such as Sapphire and Silicon Carbide.

After we make the ingot, we cut it into thin wafers, and polish it to a mirror finish.

2. Epitaxial Layer Growth

The gold standard of GaN-based LEDs is Metal Organic Chemical Vapor Deposition (MOCVD) which allows an atomic scale control of multiple quantum well (MQW) structures. These MQWs, layers of InGaN and GaN, design the bandgap to produce wavelengths of high efficiency.

3. LED Photolithography & Etching

Manufacturers produce the LED chip by way of photolithography, in which they put a light-receptive coating on the wafer and illuminate it by UV light via a mask, which forms the pattern of the chip. The undesired regions are then eliminated in development.

Then etching cuts the pattern into the semiconductor- wet etching for just simple patterns, or dry (plasma) etching when requiring finer details. Lastly, metal electrodes such as gold or aluminum are deposited to allow effective transfer of current, which prepares it to emit light.

4. LED Chip Dicing & Sorting

Wafers are diamond sawed or laser dice into thousands of bare LED chips (~0.21 mm 2 to 1 mm 2 ). We bin individual chips and sort them by forward voltage, wavelength and brightness to provide matchiness.

LED Packaging

LED packaging changes the fragile semiconductor chips into practical, durable sources of light. Each packaging step is engineering optically performance, thermal management, and long life at Casyoo.

1. Wire Bonding & Die Attachment

It all starts with die attachment LEDs – attaching the small chip (smaller than a grain of sand) to a lead frame or substrate. Manufacturers use conductive epoxy Conductive epoxy or solder paste to provide the best electrical conductivity and lowest thermal resistance.

Then through wire bonding, manufacturers use the ultra-fine gold or copper wires (25–50 um thick) to stitch the electrodes on the chip to the lead frame. This is a sub-micron step – any misalignment can cause a performance loss or failure.

2. Phosphor Coating & Color Tuning

White LEDs do not produce white light, directly – it needs an ingenious conversion. At this point, manufacturers cover a GaN blue LED chip in phosphor materials which convert a portion of the blue light into other parts of the spectrum, creating a wide, white spectrum.

Conformal coating uniformly encloses the chip, which facilitates uniform color production. Remote phosphor designs, conversely, keep the phosphor layer off the chip, which (with the assistance of a heat pipe) can aid in thermo-management, limiting long-term degradation.

3. LED Encapsulation

Encapsulation protects the LED against moisture, dust and mechano stress and directs light. The Common package types are:

- DIP (Dual In-line Package): A traditional, through-hole variety normally found mostly in indicator lamps and simple displays.

- SMT (Surface-Mount Technology): Small (e.g. 2835, 5050 sizes) and applicable to automated assembly, they are well suited to contemporary lighting systems.

- COB (Chip-on-Board): COB opts to mount several chips directly on a substrate, increasing lumen and thermal efficiency.

4. Thermal Management

Casyoo utilizes multi-layer thermal management from the process of LED packaging. To effectively conduct the heat away form the LED junction we utilize ceramic or copper-clad aluminum substrates with thermal conductivity as high as 401 W/m K. The chip is mounted with high-end thermal interface materials that ensure the reduced thermal resistance of less than 7.5 o C/W.

5. Quality Control & Testing

LEDs have to demonstrate their value after the complex chip fabrication and packaging processes before reaching the customers. Each packaged LED at Casyoo must run the gauntlet of tests that would eliminate inconsistencies and ensure long-lasting performance.

Optical Performance Testing

We test the brightness, color temperature, and color accuracy of the LED to make sure each unit operates up to par in its lighting. Batch-to-batch consistency in look and appearance is very important, especially for architectural or commercial lighting.

Electrical Characterization

The voltage and current levels are measured to ensure that there is efficient operation of the LED that is free of flicker. We also test reverse leakage so that we can detect early symptoms of impending failure.

Reliability Testing

By subjecting LEDs to heat, cold, and humidity our engineers can simulate years of use in a matter of days. These tests expose how a product will be able to perform under harsh conditions without failing with time.

Automated Optical Inspection (AOI)

AOI employs fast cameras to detect microscopic defects- non-uniformity in the coating of phosphor, improperly aligned wire bonds, or defects in the lens. Any defect is alerted the instant it happens and taken out of the production process.

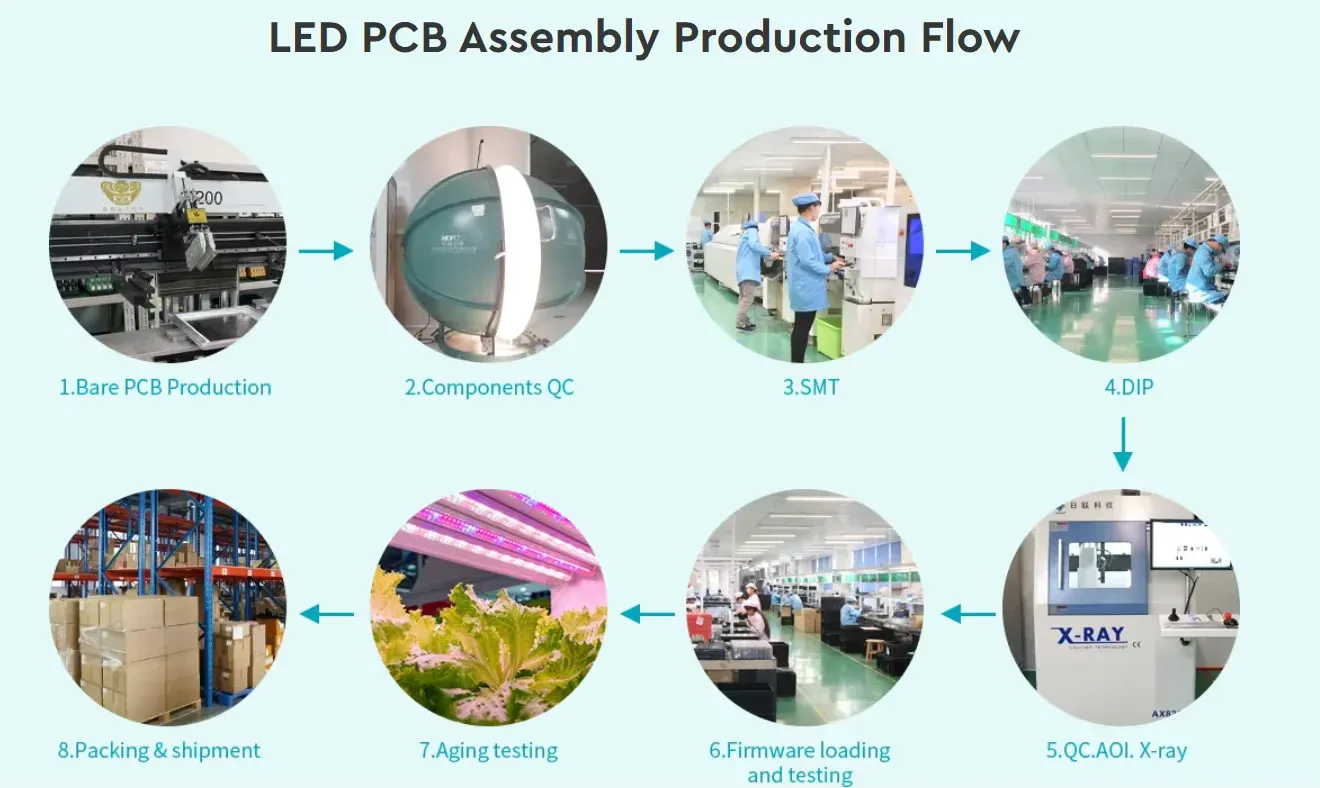

LED Assembly Process

Our work starts well ahead of assembly, where we make Design for Assembly (DFA) checks to ensure that all of the component placements are good enough to manufacture. We use standardized operating procedures to change raw PCBs into functional boards using a highly choreographed surface mount technology (SMT) process.

1. SMT Assembly

- Solder Paste Printing: A stencil made of stainless-steel applies defined quantities of lead-free solder paste to PCB pads onto which components are placed.

- Component Mounting: LEDs, drivers, and microcomponents are placed by high-speed pick-and-place machines with +/- 25um accuracy – quicker than the eye can blink.

- Reflow Soldering: A multi-zone oven passes the boards through carefully controlled temperatures (up to 240-260 C) which melt the solder paste, creating permanent electrical connections without causing thermal stress.

2. LED Driver Integration

We begin with the LED array specific “personality” analysis of forward voltage, current needs, and thermal behaviour. To avoid current fluctuations that destroy LEDs, we suggest using constant-current drivers on most applications. Our engineers carefully compute designs – e.g. for a 10W system with 2835 LEDs, we will use 3 parallel strings of 7-series LEDs to make sure that the illumination is uniform without damaging components with excess current.

3. LED Optical Design

Casyoo precisely sculpts light for optimum visual experiences and efficiencies by using a two-stage procedure. It is one of the core steps of led street light manufacturing process.

Primary Optics is first directed at optimizing light extraction from every LED chip through custom-molded lenses with more than 90% efficiency.

Then, Secondary Optics provides delivery of light in a specific manner. Our reflector systems manage beam angles to a variety of applications, such as accent lighting to warehouse light. Reflector arrays produce custom patterns such as glare-free office lighting at efficiencies greater than 92%. And when the needs are complex we employ hybrid solutions where we use a combination of both.

We test our designs with goniophotometer testing and CIE colour mapping to ensure flawless colour uniformity (SDCM < 3) across the beam. With our anti-glare technologies, we minimize UGR to below 16, which means visual comfort in any high-luminance environment.

4. LED Enclosures & Heat Management

Aluminum alloy is by far the most popular material in the housing of LED lights, due to its good heat dissipation capacity, light weight and durability, most high-power and outdoor LED lights housing use aluminum alloy. Other plastics such as PC (polycarbonate) are common due to their cost-efficiency, resistance to impact, and design flexibility, commonly in lower-power indoor lighting or as diffusers/lenses in combination with aluminum.

During assembly, we maximize heat dissipation by using engineered aluminum heat sinks having 12-25 fins per inch to provide maximum natural convection cooling. In concentrated heat loads, we embed vapor chambers which distribute heat better than solid metals.

5. Final Scrutiny

After we finish making the LED light fixtures including adding LED beads, drivers, heat sinks, optical components, and housing, we test the whole product regarding performance and safety issues one more time. Like the tests we conduct at the LED packaging phase, we re-confirm optical performance and system-level electrical safety testing. We conduct additional environmental and reliability tests peculiar to the finished product and total lumen maintenance testing.

Standardization & Certification

Casyoo is ISO, CE, UL, BSCI, FCC and RoHS certified- this is an indication of our commitment to quality, reliable LEDs that have a long life span, less environmentally threatening, and with maximum output. The Certification Process involves:

- Laboratory Testing: In accredited labs, we implement strict electrical, optical and environmental tests.

- Documentation Review: User manuals, material declarations and technical files should be according to the regional regulations.

- Factory Audits: The consistency and safety are checked in the manufacturing processes.

Why choose Casyoo?

- Full-Scale Customization

We have OEM/ODM capacities that give you what you specifically want- chip design to luminaire finishing. Our state-of-the-art SMT lines, automated optical inspection (AOI) and high-precision molding systems transform ideas into reality within the shortest period of time and in high quality.

- Reliability Built on Rigor

All products are tested on three levels (component, module and finished goods) and are CE/UL/RoHS/ISO certified. LM-80 and TM-21 reimbursement Lumen maintenance testing guarantees life over 50,000 hours.

- End-to-End Support

We have the engineering support of 70+ engineers, 100 sales specialists, and 25 procurement experts to advise you technically on your way to prototype and mass production. We have a 12,400 m² factory that allows quick turnaround, and our strategic raw material stocking reduces lead times.