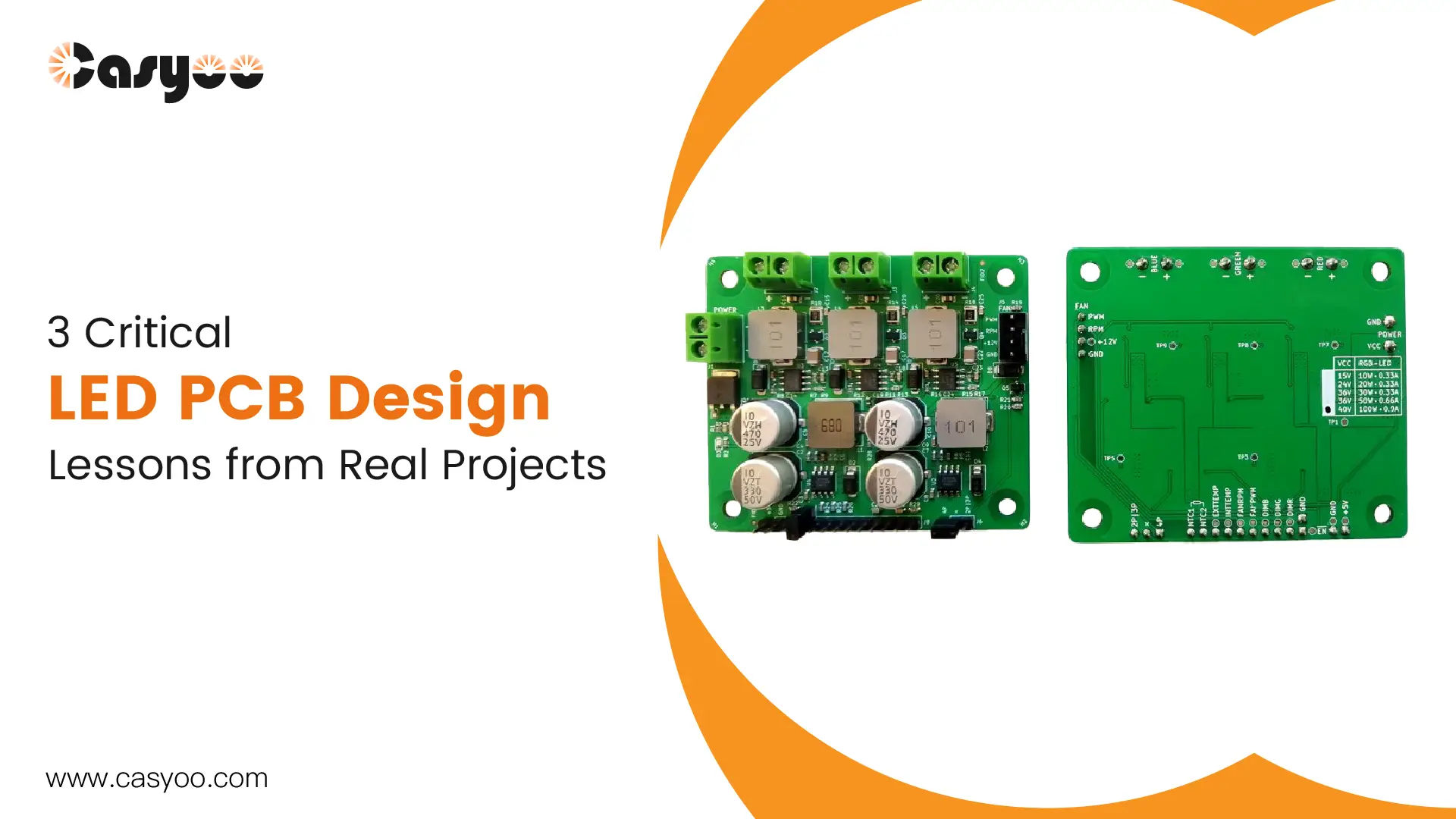

In commercial horticulture, crop yields do not only rely on cultivation; successful, high-performance light is also a prerequisite. Grow lights need to provide stable photon output, optimized spectrum, electrical and thermal safety, long lifespan, and easy integration. At Casyoo, we design and produce fully integrated grow lighting systems capable of satisfying these requirements. This is a synthesis of optical, thermal, and electrical design to provide in vertical farms, greenhouses, and indoor grow facilities.

The following case study spotlights a recent project in which we assisted a Canadian customer with high-efficiency 109W LED grow light panels and specially matched modular driver cabinet system. Our solution offers well-groomed voltage conversion, dimmed compatibility, and stability of electricity in a demanding commercial environment.

The Challenge

Our Canadian client operates a large-scale indoor cultivation facility and was seeking a high-efficacy grow light solution. They were impressed with the performance metrics, heat dissipation, and the construction of our 109W full-spectrum LED panel.

There was, however, one technical incompatibility issue which stood in the way. The Canadian input power supply is 110V AC, and the 109W grow light panel runs at 56V DC input. Consequently, the grow light panels could not be directly connected to the existing electrical infrastructure at the site.

Without a comprehensive and stable power conversion and control system, the LED panels’ complete potential could not be tapped.

Furthermore, for the client’s cultivation situation, we also predicted the possibility of requiring centralized dimming control, ease of deployment and maintenance, and a scalable design appropriate for future growth.

The Solution

To meet the technical gap and offer a system that could be used immediately, we had our designers and engineers collaborating to devise a driver cabinet that could:

- Converting 110V AC input into 56V DC

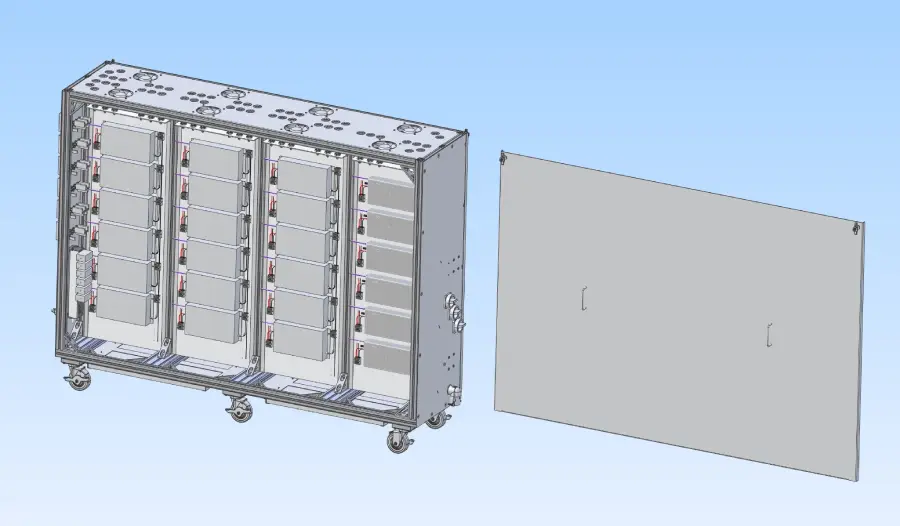

- Driving large sets of panels (48 units per cabinet)

- Offering dimming control, thermal management and mechanically durable construction

System Breakdown

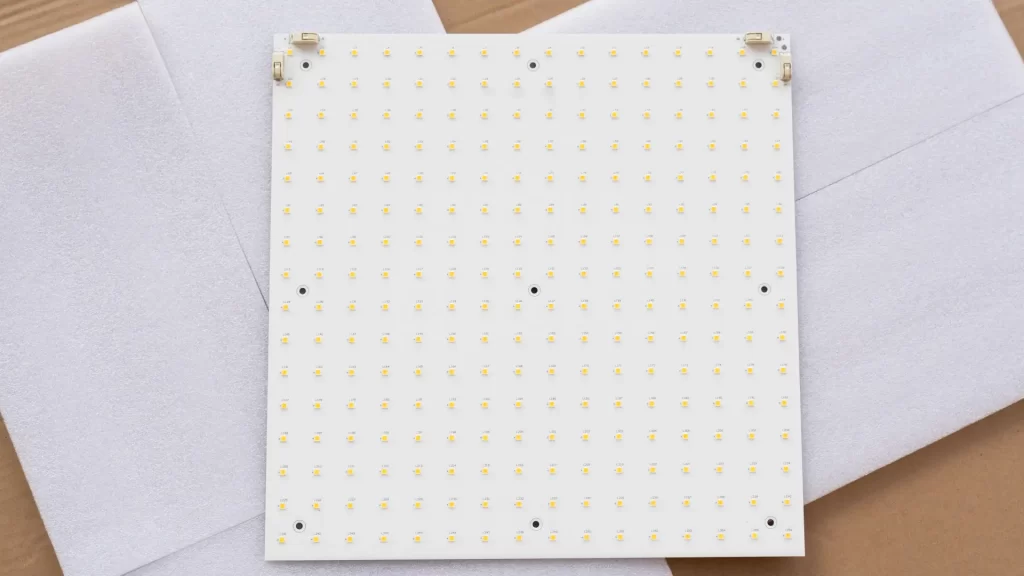

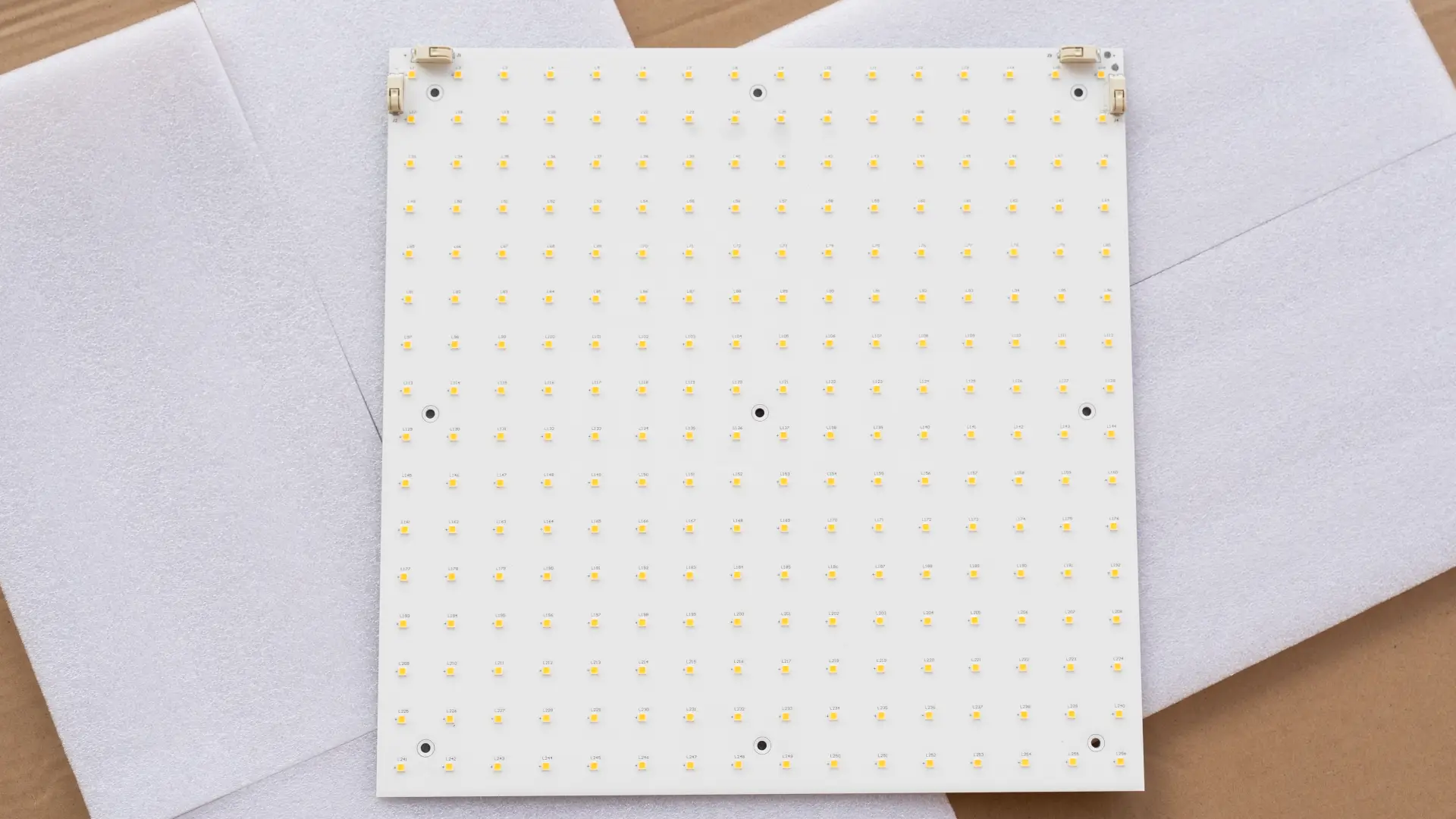

- Each 109W LED panel is a square module, optimized for uniform canopy coverage.

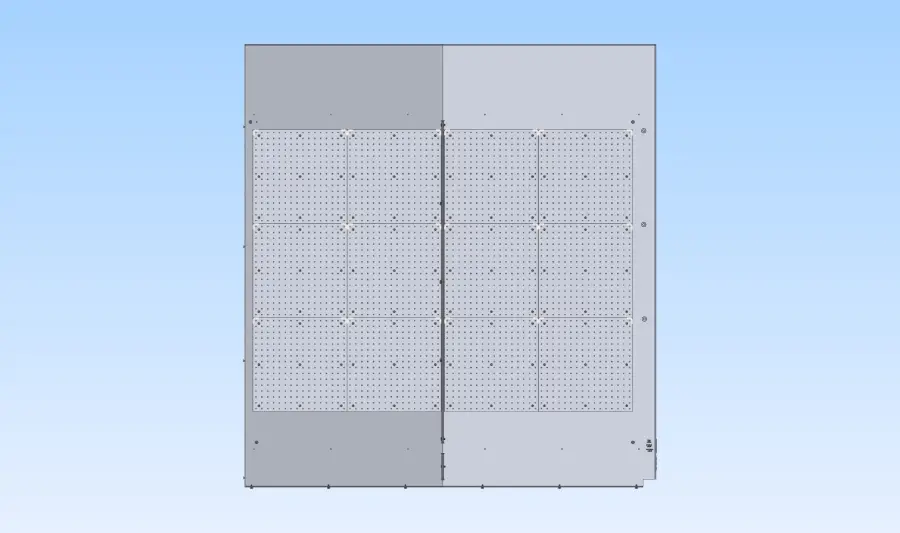

- We assembled the system into 400 complete units, where each unit consists of 12 LED panels, forming a modular lighting array.

- Each set of 48 panels is powered by one integrated driver system, consisting of 6×800W high-efficiency constant-current LED drivers. They are custom-configured into a rolling cabinet for ease of movement and maintenance.

Design Highlights of the Driver Cabinet

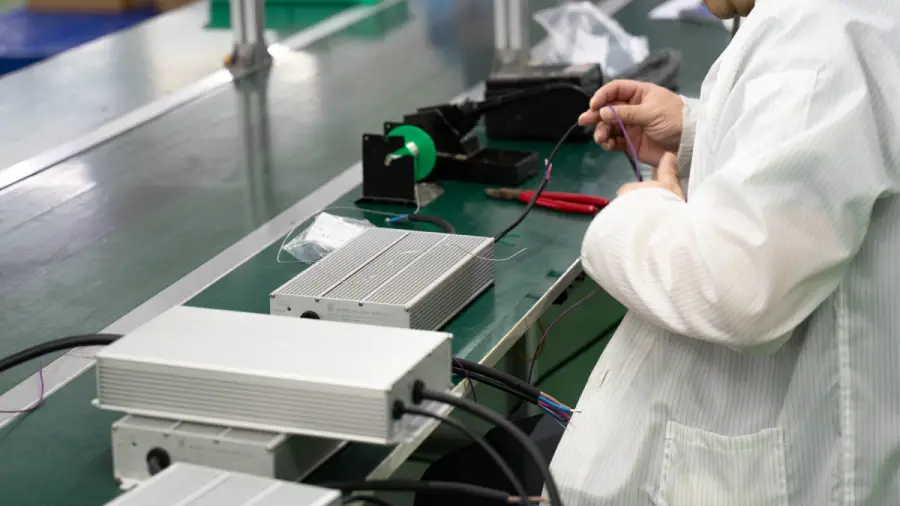

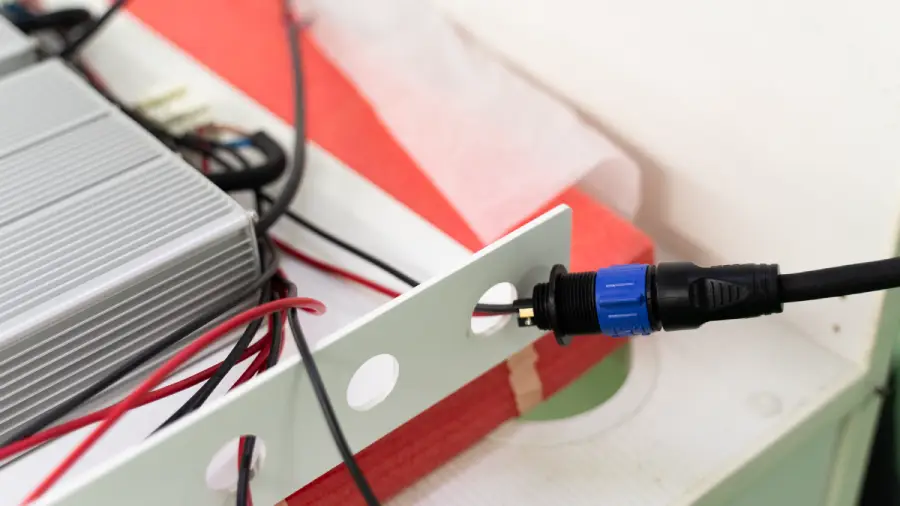

- Industrial-grade enclosures with integrated cable routing and connectors

- High precision heat management through active ventilation and metal heat-dissipation design

- Lockable caster wheels for safe mobility within the facility

- Driver protection features: Overcurrent, short circuit, and temperature feedback

- Fully compliant with North American electrical safety standards

The Results

After installation, the 12-panel light boards gave wide, even coverage and provided uniform light intensity over the plant canopy.

By pairing the panels with our external modular driver system, we ensured that the client’s 110V infrastructure was fully compatible with our 56V panels—without requiring facility-level electrical redesign.

Customer Benefits Realized:

- Voltage Compatibility Solved: System driver allowed immediate use with reliable and efficient conversion of 110V to 56V DC.

- Improved Electrical Safety: With the use of external constant-current driver systems, current to each light panel was very stable and within the safe limits, eliminating the danger of overheating, voltage surges, or irregular operation.

- Enhanced Control: With the ability to control the light to fit the plants growth cycle (e.g., seedling, veg, flower), the integrated dimming provided more efficient energy output and crop vigor.

- System Scalability: With each cabinet driving 48 light modules, deployment was modular and easy to expand.

- Thermal Stability: Thermal stress was also low due to accurate current regulation and superior heat-dissipation in both light panels and drivers.

The client was enthusiastic about the clean, deployment-ready design of the system where each piece was labeled and already put together which spilled over to save a lot of time during their installation. They further pointed out that this solution indicated a profound comprehension of commercial cultivation processes to combine power conversion and dimming power control, ensuring good performance and the simplicity of use in the grow floor.

Casyoo Brings Ideas to Life

From design to production, Casyoo provides a full-spectrum service including:

- Custom LED grow light design

- Driver and power system development

- Prototyping and testing

- Complete pre-assembly, wiring, and packaging

- Logistics support and deployment consulting

This project is a showcase of the way of how we turn client challenges into totally integrated and professionally engineered solutions. Whatever growing project you want to pursue, be it an indoor farm, greenhouse, or a high-density hydroponic operation, we have you covered.

All you need to do is explain your idea or need to us, and we will take it further: we will refine your idea to make it viable, and create a working engineering design, and then assemble and make ready a plug-and-play system that you can just move into place and start using.

Contact Casyoo and let your vision become a high-performance reality!